Understanding HVAC Installation and Repair Essentials

Heating, ventilation, and air conditioning underpin everyday comfort, health, and energy bills, yet the path from quotation to a smooth, quiet system is full of decisions that shape performance for years. Whether you care for a compact apartment or a sprawling office, the essentials remain consistent: accurate load calculations, thoughtful duct and equipment design, careful installation, and diligent maintenance. This article brings those moving parts into focus, so you can navigate choices with clarity—and enjoy dependable, efficient indoor comfort.

Outline:

– Heating installation fundamentals: loads, equipment types, efficiency metrics, and safety.

– Ventilation and indoor air quality: airflow targets, filtration, and energy recovery.

– Air conditioning: refrigeration basics, sizing, commissioning, and refrigerants.

– Repair and maintenance: diagnostics, preventive care, and service planning.

– Bringing it together: budgets, timelines, contractor selection, and a practical checklist.

Heating Installation Essentials: From Load Calculations to Safe Start-Up

Heating succeeds or fails before the first screw is turned. The cornerstone is an accurate load calculation that accounts for climate, building size, insulation levels, window performance, infiltration, and internal gains. Industry-standard methods translate these inputs into how many BTUs per hour a space actually needs on a design winter day. Oversizing seems harmless but often causes short cycles, uneven temperatures, higher fuel use, and noisy operation. Undersizing leaves rooms cold at the very moments comfort matters most.

With the load defined, compare equipment paths. Furnaces convert fuel to heat, with modern models reaching AFUE ratings in the mid‑90s, meaning most energy becomes usable heat. Boilers supply hydronic systems that can pair with radiators or in-floor radiant loops for smooth, even warmth; condensing designs reclaim additional heat from exhaust for higher efficiency. Heat pumps move heat rather than make it, delivering noteworthy performance in moderate climates and increasingly viable output in colder regions thanks to improved compressors and controls; efficiency can be expressed as HSPF2 or as a seasonal coefficient of performance. Each option carries trade-offs in fuel availability, installation complexity, venting, and maintenance habits.

Installation quality is where even premium equipment can be let down. Key steps include:

– Performing Manual J–style load calculations and documenting results.

– Matching capacity to loads and selecting compatible airflow and control strategies.

– Designing ducts via recognized methods, sealing joints with mastic, and verifying static pressure.

– Providing correct combustion air, clearances, and venting for fuel-fired systems.

– Running dedicated electrical circuits, verifying polarity and grounding, and labeling shutoffs.

Safety is non-negotiable. Spill switches, pressure switches, and flame safeguards must be tested. Flue piping needs proper pitch and support; condensate from condensing appliances requires neutralization and a reliable drain path. Carbon monoxide alarms outside sleeping areas are a simple, vital layer of protection. Before handoff, commissioning should verify temperature rise, manifold gas pressure (if applicable), and airflow. The result is a system that lights safely, warms evenly, and responds predictably when the thermostat calls—no drama, just steady comfort.

Ventilation and Indoor Air Quality: Fresh Air, Filtration, and Balanced Pressure

Ventilation keeps indoor air from going stale, dilutes pollutants, and manages humidity. A practical target for many homes is continuous or intermittent mechanical ventilation sized to occupancy and floor area, aligning with well-established guidelines. In offices and shops, ventilation rates are tailored to use patterns and occupant density. The goal is steady, predictable air exchange without creating pressure imbalances that invite drafts, moisture issues, or combustion safety problems.

There are three common approaches. Exhaust-only systems pull air out through bath and kitchen fans, drawing makeup air through cracks and dedicated inlets; they are simple but can depressurize a building. Supply-only systems push filtered outdoor air in, slightly pressurizing the space and relying on exfiltration to exit; they manage intake quality but can drive warm air into hidden cavities in winter. Balanced systems pair supply and exhaust, often through heat or energy recovery ventilators (HRVs/ERVs) that transfer heat—and, in the case of ERVs, some moisture—between outbound and inbound streams. Recovery effectiveness commonly ranges around 60–80%, trimming the energy penalty of fresh air.

Filtration matters as much as airflow. A properly sealed return path with a filter in the MERV 8–13 range can capture much of the dust, dander, and fine particles typical in indoor environments, while higher MERV filters may require duct and blower designs that can handle increased resistance. Keep relative humidity around 30–50% to reduce mold risk and improve comfort; dehumidification in summer and humidification in dry winters can be integrated cautiously, with a watchful eye on surfaces that could accumulate moisture.

Design details determine outcomes:

– Size ventilation based on area and occupancy, not guesswork.

– Route outdoor air intakes away from exhausts, garages, and standing water.

– Seal ducts with mastic, not tape alone, and verify leakage with testing.

– Use short, straight duct runs for exhaust fans; every bend is a penalty to flow.

– Balance systems to neutral or slightly positive pressure in living areas.

Measured data closes the loop. A simple manometer reading of static pressure can warn of filter loading or duct restrictions. Carbon dioxide trends, while not a pollutant limit by themselves, give a window into ventilation sufficiency in busy rooms. When ventilation, filtration, and humidity control work together, occupants tend to feel more alert, odors dissipate faster, and surfaces stay dry—quiet signs that the air you cannot see is being carefully managed.

Air Conditioning Fundamentals: Sizing, Refrigerants, and Careful Commissioning

Air conditioning is a heat transfer story: refrigerant absorbs heat indoors, rejects it outdoors, and repeats the cycle until the thermostat is satisfied. Evaporators run cold to pull heat and moisture from indoor air; condensers run warm to release that heat to the outside. Compressors pump the refrigerant through the loop, and metering devices set the pressure drop that enables evaporation indoors. Behind the scenes, airflow does as much work as refrigerant—without adequate air moving across the coil, performance falls, efficiency slides, and coils can freeze.

Right-sizing follows the same logic as heating: calculate cooling loads based on orientation, window solar gain, insulation, occupancy, appliances, and infiltration. Oversized systems cool too quickly to dehumidify effectively, leaving a clammy feel. A common airflow target is roughly 350–450 cubic feet per minute per ton of cooling, adjusted for climate and dehumidification goals. Efficiency metrics such as SEER2 (seasonal) and EER (steady-state) summarize performance; higher numbers typically mean lower energy use under comparable conditions. Variable-speed and staged systems can modulate capacity, staying closer to the load and improving comfort while trimming energy use during part-load operation.

Refrigerant choices are evolving. Many markets are phasing down higher global-warming-potential HFCs in favor of lower-GWP options like R‑32 or R‑454B. These newer refrigerants may carry different pressure and handling characteristics, and some are classified as A2L, requiring attention to charge quantity, leak detection, and ventilation clearances. Proper training and adherence to codes are essential for safe, compliant installations.

Commissioning is where the magic becomes measurable:

– Verify total external static pressure and compare to blower tables.

– Set fan speeds to meet airflow targets and adjust for dehumidification needs.

– Measure superheat and subcooling to confirm correct refrigerant charge.

– Insulate and support line sets, and install a liquid-line filter drier where applicable.

– Test condensate drainage and add a float switch to prevent overflows.

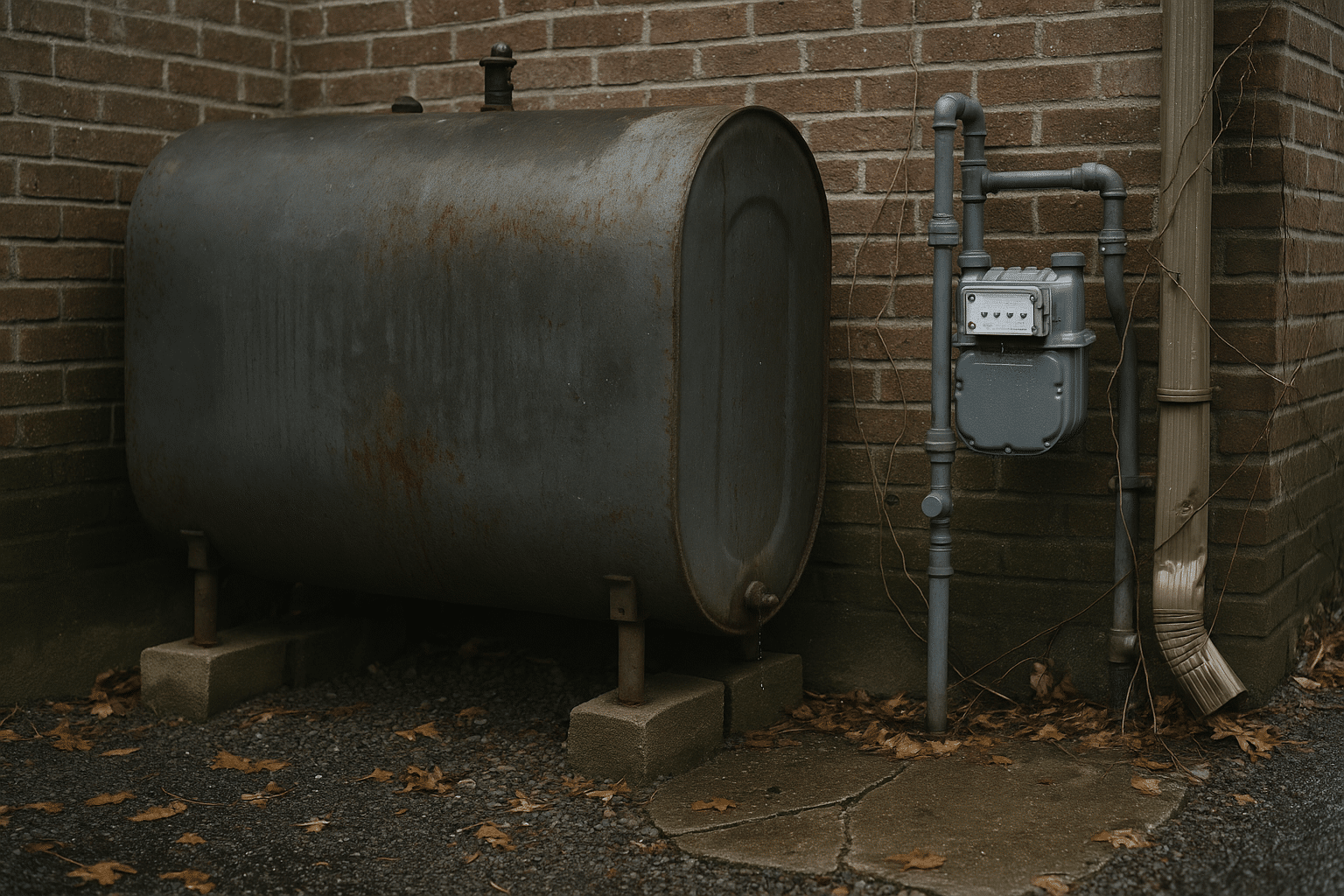

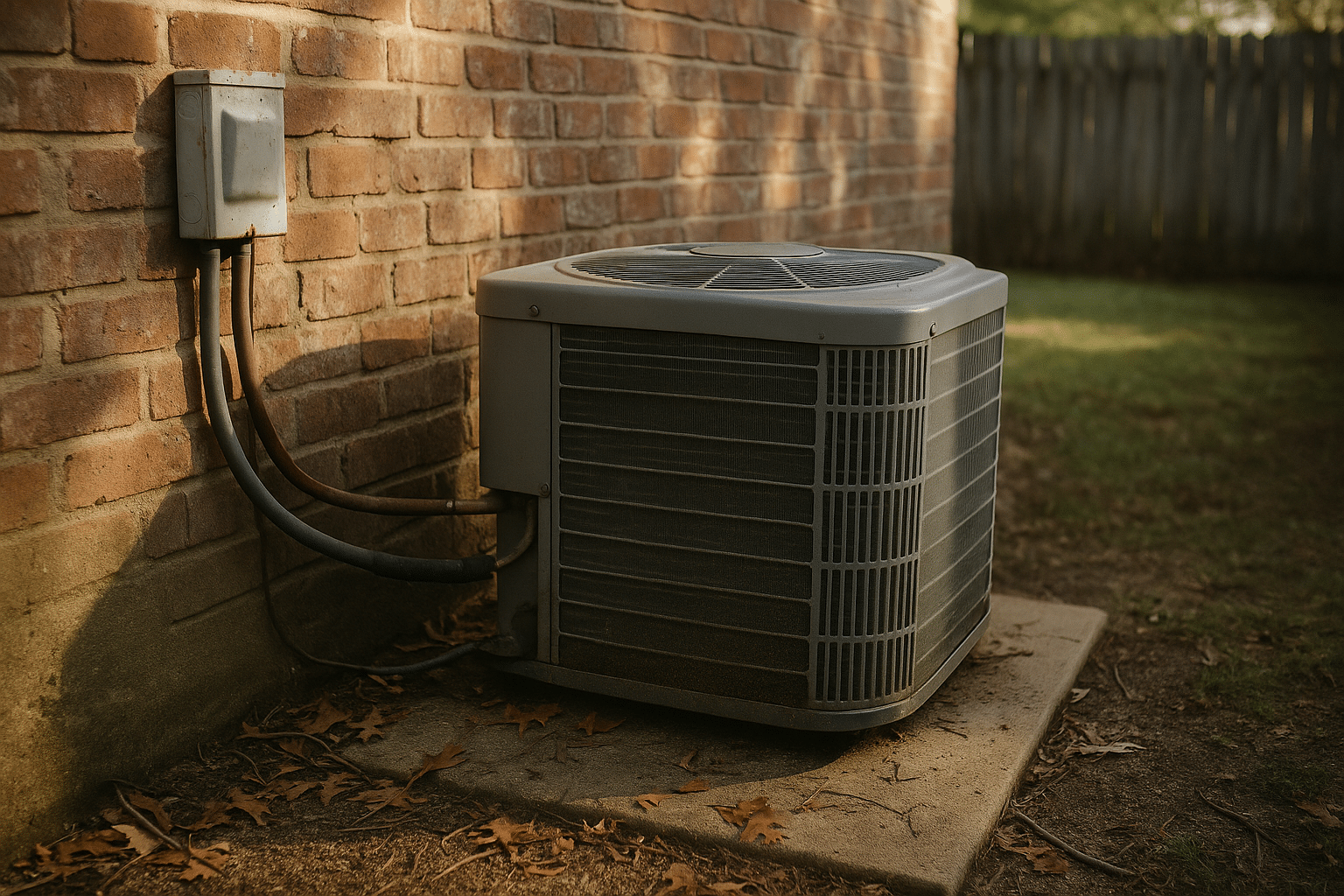

Acoustics and placement matter for livability. Outdoor units prefer stable pads, clear airflow, and distance from bedrooms; even modest decibel differences are noticeable at night. Indoors, good return placement and sound-dampening takeoffs can tame whoosh and rattle. With a thoughtful start-up and a brief owner walk-through—filter locations, thermostat settings, and seasonal tips—the system is far more likely to sail through summer without surprise service calls.

Repair and Maintenance: Diagnosing Issues and Extending System Life

Well-built HVAC systems are sturdy, but they’re not set‑and‑forget. Airflow restrictions, sensor drift, and simple grime slowly push performance off course. A routine maintenance rhythm is the antidote, and it starts with the parts you can touch: filters, coils, drains, belts, and outdoor clearances. Filters generally need checking every 1–3 months; clogged media is a leading cause of short cycling and coil icing. Outdoor condensers should breathe freely, with vegetation trimmed and fins gently cleaned to remove lint, seeds, and dust. Indoor coils benefit from annual inspection and cleaning if fouled—clean coils pull more moisture, cool faster, and use less energy.

Common symptoms and what they hint at:

– Warm air when cooling: low refrigerant charge, blower issues, or a dirty coil.

– Ice on lines: airflow too low, metering device faults, or low ambient operation.

– Burning odor on heat start-up: dust on electric elements, but still worth a safety check.

– Uneven rooms: duct leakage, blocked registers, or poor balancing.

– High bills: creeping setpoints, drifting sensors, or failing motors.

Technicians use a few telltale measurements to separate guesswork from facts. Static pressure pinpoints duct restrictions. Temperature rise on heat confirms combustion or electric element output and airflow alignment. Superheat and subcooling readings indicate refrigerant charge accuracy and metering health. Electrical tests—voltage, amperage, and capacitance—catch failing contactors and capacitors before they strand equipment on a hot afternoon.

Planned service pays off in fewer emergencies and longer equipment life. A sensible schedule includes a heating check in fall and a cooling check in spring, with a written report noting readings and any recommended corrections. Homeowners and facility teams can help by keeping returns unblocked, replacing filters on schedule, and walking the property after storms to clear debris from outdoor units. If a repair is needed, weigh short-term fixes against component age and efficiency: a mature system with repeated calls might be signaling that a staged upgrade is the wiser path. Document everything; service history shortens future diagnostics and supports warranty claims where applicable.

Putting It All Together: Plans, Budgets, and a Smart Path to Comfort

Great HVAC outcomes start with a plan that respects the building as a system. Instead of jumping straight to equipment, begin with the envelope: air sealing and insulation can shrink loads enough to downsize machinery, cut noise, and reduce operating costs. Next, pair loads to equipment that fits your climate, fuel options, and comfort goals, and insist on a design that includes duct layouts, airflow targets, and control strategies you can understand. When that plan becomes a proposal, clarity is your friend—line items should explain what’s included and what commissioning steps will be performed.

Before signing, consider a simple procurement checklist:

– Request a room-by-room load calculation and keep a copy.

– Ask for duct design details, static pressure targets, and filter size and MERV.

– Confirm ventilation strategy, including any HRV/ERV specifications and balancing.

– Review thermostat capabilities, zoning logic, and setpoint limits.

– Verify permits, inspections, and start-up documentation are included.

Timelines and budgets benefit from realism. Factor lead times for equipment, especially during peak seasons, and schedule projects to avoid extreme weather if possible. Build in space for field adjustments—old homes reveal surprises when ducts meet framing, and commercial sites may have access limits. Consider long-term costs by looking beyond upfront price to energy use, maintenance, and anticipated lifespan. Variable-speed equipment, energy recovery ventilation, and well-sealed ducts often return their premium through lower bills and better comfort, particularly in climates with long heating or cooling seasons.

For homeowners and facility managers alike, confidence grows from understanding and documentation. Keep a binder—or a shared drive—with manuals, wiring diagrams, serial numbers, balance reports, and service logs. Label panels, shutoffs, and filters so anyone on the team can act quickly in an outage. If you ever sell the property, this organized record adds credibility and can ease inspections. Most importantly, it keeps your system transparent, maintainable, and resilient—so the air feels right, the bills stay predictable, and comfort becomes background music rather than a daily worry.